Insulation Chemicals

Mastics

Primary Mastic SHC 104-90

COLOR

White

APPLICATION TOOL

Trowel, Rubber glove

AVERAGE WEIGHT / LITER (ASTM D 1475)

1.25 ±0.05 kg/Liter

AVERAGE NON-VOLATILE (ASTM D 2369)

42% ±2.0 by volume 60% ±2.8 by weight

COVERAGE RANGE (SHTM 13)

(Subject to type of surface and nature of material being coated) 2.6 kg/m²

Wet Film Thickness: 2.1 mm

Dry Film Thickness: 0.9 mm

DRYING TIME (25°C 50%RH) (ASTM D 1640)

Set To Touch: 5 hours

Dry Through: 48 hours

SERVICE TEMPERATURE LIMITS (SHTM 08)

(Temperature at coated surface) -46°C ~ 104°C

WATER VAPOR PERMEANCE (ASTM E 96)

0.024 perms @ 1.3mm DFT

WET FLAMMABILITY (ASTM D 3278)

Flash Point : ≥43°C

SURFACE BURNING CHARACTERISTICS (ASTM E 84)

Class 1 or A

REMARKS

Store and apply between 4°C and 38°C.

Contains no asbestos, lead, mercury or mercury compounds.

Always test plastic material for compatibility when using a solvent base product.

Mastics

Primary Mastic Adhesive Insulation SHC 104-91

COLOR

Gray

APPLICATION TOOL

Trowel, Rubber glove

AVERAGE WEIGHT / LITER (ASTM D 1475)

1.25 ±0.05 kg/Liter

AVERAGE NON-VOLATILE (ASTM D 2369)

42% ±2.0 by volume 60% ±2.8 by weight

COVERAGE RANGE (SHTM 13)

(Subject to type of surface and nature of material being coated) 2.6 kg/m²

Wet Film Thickness: 2.1 mm

Dry Film Thickness: 0.9 mm

DRYING TIME (25°C 50%RH) (ASTM D 1640)

Set To Touch: 5 hours

Dry Through: 48 hours

SERVICE TEMPERATURE LIMITS (SHTM 08)

(Temperature at coated surface) -46°C ~ 104°C

WATER VAPOR PERMEANCE (ASTM E 96)

0.024 perms @ 1.3mm DFT

WET FLAMMABILITY (ASTM D 3278)

Flash Point : ≥43°C

SURFACE BURNING CHARACTERISTICS (ASTM E 84)

Class 1 or A

REMARKS

Store and apply between 4°C and 38°C.

Contains no asbestos, lead, mercury or mercury compounds.

Always test plastic material for compatibility when using a solvent base product.

Mastics

WB Weather Barrier Mastic SHC 103-35

COLOR

White

APPLICATION TOOL

Trowel, Glove

AVERAGE WEIGHT / LITER (ASTM D 1475)

1.39 ±0.05 kg/Liter

AVERAGE NON-VOLATILE (ASTM D 2369)

64% ±3.0 by volume 74% ±3.5 by weight

COVERAGE RANGE (SHTM 13)

(Subject to type of surface and nature of material being coated) 3.5 kg/m²

Wet Film Thickness: 2.5 mm

Dry Film Thickness: 1.6 mm

DRYING TIME (25°C 50%RH) (ASTM D 1640)

Set to touch: 3 hours

Dry through: 16 hours

SERVICE TEMPERATURE LIMITS (SHTM 08)

(Temperature at coated surface) -29°C ~ 93°C

WATER VAPOR PERMEANCE (ASTM E 96)

≤1.0 perms @ 1.6mm DFT

WET FLAMMABILITY

No Flash Point in wet state

SURFACE BURNING CHARACTERISTICS (ASTM E 84)

Class 1 or A

VOCs (US EPA Method 24)

<50 g/L

REMARKS

Store and apply between 4°C and 38°C.

Contains no asbestos, lead, mercury or mercury compounds.

Protect from freezing until dry.

Do not apply if rain is expeced in 16 hours.

Always test foil and paper facings for acceptable adhesion before using.

Vapour Barrier Insulation

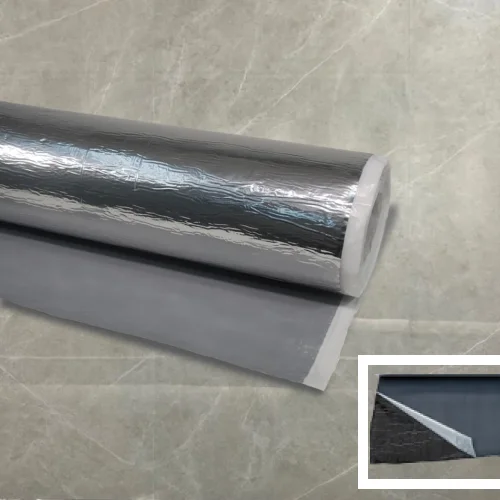

Buseal Wrap - Vapour Barrier Insulation (SHC 700-121)

COLOR

Aluminum-Black

COMPOSITION

Aluminium foil faced Butyl wrap

12㎛ PET+25㎛ AL+12㎛ PET+Butyl Rubber Compound (Others available on requests)

DENSITY

1.50 ± 0.05 g/㎤

DIMENSION

Thickness: 1.2㎜ ±5%

Width: 1meter

Length: 15meter

(15㎡ Roll)

SERVICE TEMPERATURE LIMITS

- 40 ~ 121℃

WATER VAPOR PERMEANCE (ASTM E 96)

< 0.02 metric perms

SURFACE BURNING CHARACTERISTICS (ASTM E84)

Class 1 or A

ADHESION STRENGTH (ASTM D1000)

≥ 10 N/cm

ELONGATION (ASTM D1000)

≥ 30%

TENSILE STRENGTH (ASTM D1000)

≥ 60 N/cm

BREAKING STRENGTH (ASTM D1000)

Over 80 N/10㎜

REMARKS

Store and apply between 0℃ and 40℃.

Contains no asbestos, lead, mercury or mercury compounds.

BUSEAL® WRAP 12 is compatible with most kinds of substrates.

BUSEAL® WRAP 12 should be applied on clean surfaces free from moisture, foreign materials, oil and any contaminations.

Cut BUSEAL® WRAP 12 to size, apply and press down firmly, preferably with a roller.

Be sure to remove release liner gradually to avoid wrinkling.

Sealant

Metal Jacketing Sealant (SHC 105-03) Thermal Insulation

COLOR

Aluminum

APPLICATION TOOL

Trowel, Caulking gun

AVERAGE WEIGHT / LITER (ASTM D 1475)

1.10 ±0.05 kg/Liter

AVERAGE NON-VOLATILE (ASTM D 2369)

58% ±2.7 by volume, 65% ±3.0 by weight

COVERAGE RANGE (SHTM 13)

(Subject to type of surface and nature of material being sealed)

Trowel : 2.4 kg/㎡

Wet Film Thickness: 2.2 mm

Dry Film Thickness: 1.3 mm

caulking gun : 9m/tube @6.4mm Bead

DRYING TIME (25℃ 50%RH) (ASTM D 1640)

Set To Touch: 1 hour

Dry Through: 72 hours

SERVICE TEMPERATURE LIMITS (SHTM 08)

-40℃ ~ 121℃

WATER VAPOR PERMEANCE (ASTM E 96)

0.014 perms @2.38mm DFT

WET FLAMMABILITY (ASTM D 3278)

Flash Point : ≥41℃

SURFACE BURNING CHARACTERISTICS (ASTM E 84)

Class 1 or A

REMARKS

Store and apply between 4℃ and 38℃. Contains no asbestos, lead, mercury or mercury compounds.

Sealant

VT-210 High Performance Sealant

Singapore Green Building Product Labelling Scheme (SGBPLS) compliant

ASTM C920 (Class 50) compliant

AS/NZS 4020:2005 (Potable water test) compliant

FDA 21 CFR Part 175.300 (Safe food contact) compliant

Excellent weathering resistance

Permanently flexible